Involve your team at every step.

Tell us want you want, sit back and let us give you just that.

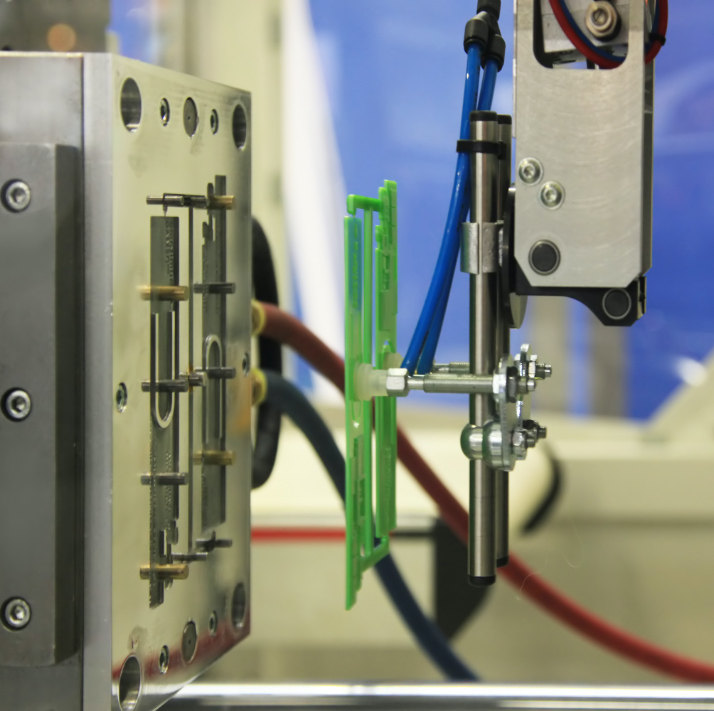

Share your ideas and let our experienced design

and engineering teams transform them into real

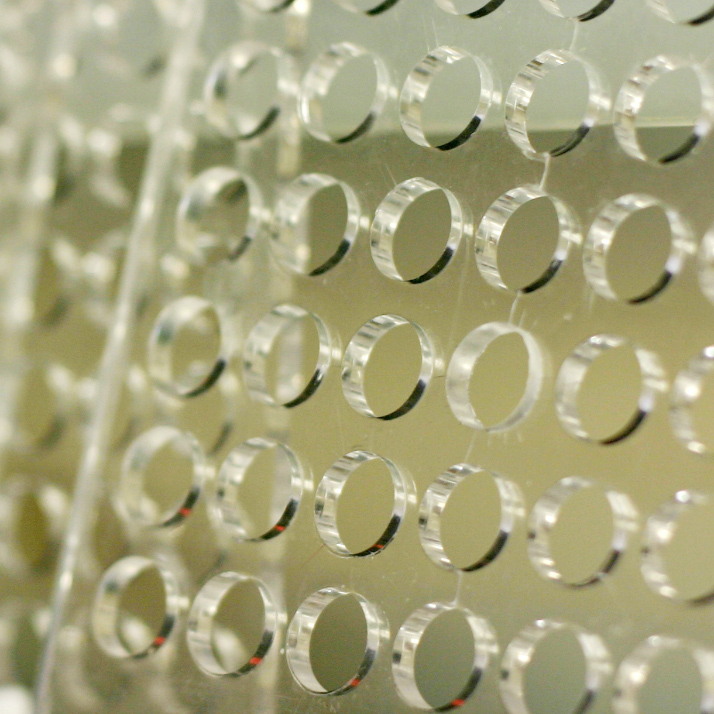

products. We are able to design and develop in

an array of materials ranging from metals, plastics

and wood.

During this process, designs are tweaked

production methods optimised and anything that

is not right, is simply done again.

We do not cut corners.

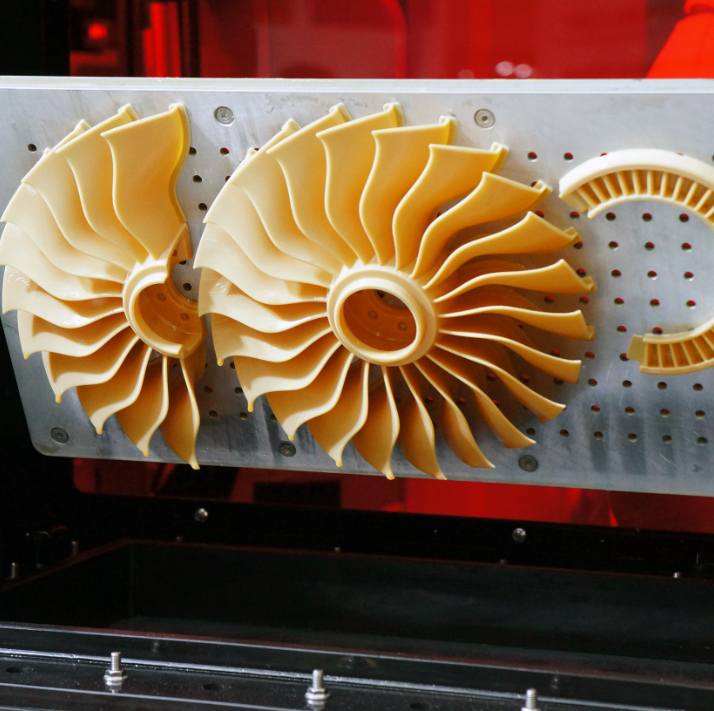

We deliver excellent solutions to companies operating in an array of industries, including tobacco, cosmetics, FMCG’s and consumer electronics.

Our experience and know-how in a wide range of materials and production methods, together with our approach to quality and customer dedication, ensures that nothing sub-standard ever leaves our premises.

Regardless of the order quantity or the opportunities the projects may bring, our products will always be

competitively priced, value engineered and finished to a premium standard.

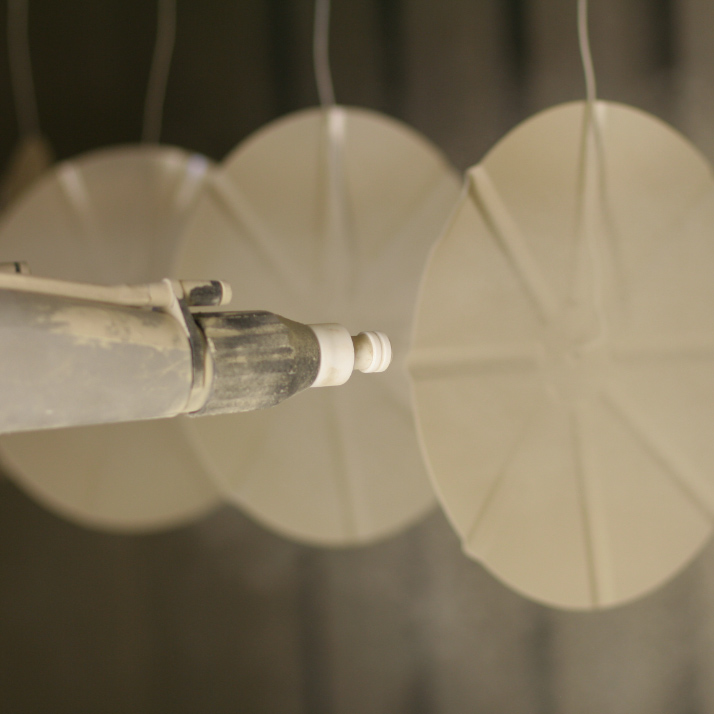

Panavend offers solutions that cover the whole production cycle from design, prototyping and tooling up to the actual production of the parts required, both with plastic injection and

thermoforming.

By using different production methods we

are able to provide services for both small and large runs.

Depending if it is a road, air or sea delivery, we will transport your products to your facilities with the

appropriate packaging, safely and in one piece. If you wish us to send these products to multiple locations, packaging and production methods can be tweaked in order to accommodate this request

as well.

If you would like to store your products with us for

future deliveries we would be able to accommodate this request and regardless of the size of the projects or worldwide location, if installation is required we will manage this delicate process too.